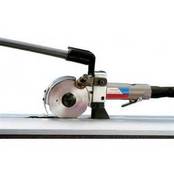

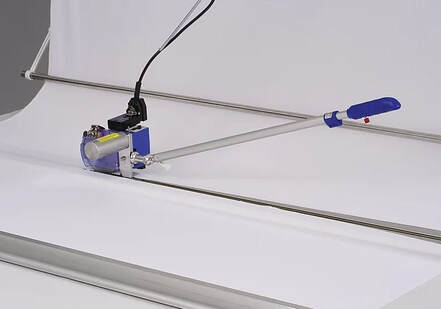

If you're in the market for an end cutter machine in 2024, you're in luck. These machines have evolved significantly over the years, offering improved performance, precision, and efficiency. Whether you're in the textile, apparel, or manufacturing industry, choosing the right end cutter machine is crucial for streamlining your operations. In this guide, we'll explore the key factors to consider and provide recommendations for the best end cutter machines in 2024. 2. Cutting Width: The cutting width determines the maximum size of the materials you can work with. You are going to want to make sure the machine you choose can handle the width of the materials you typically use in your production process. 3. Accuracy and Precision: Look for an end cutter machine that offers high accuracy and precision in cutting. Clean, precise cuts are essential for minimizing material waste and achieving consistent results. 4. Speed and Efficiency: Efficiency is a key consideration for any manufacturing process. The cutting speed of the machine can significantly impact your production rates. Choose a machine that balances speed with accuracy to meet your requirements. 5. Durability: A durable machine is an investment that pays off in the long run. Consider the build quality, materials, and construction of the machine to ensure it can withstand regular use in an industrial setting. 6. Safety Features: Safety should always be a top priority. Look for machines that come equipped with safety features such as protective guards, emergency stop buttons, and safety sensors to prevent accidents. 7. User-Friendliness: An easy-to-use interface and intuitive controls can save you time and reduce the learning curve for your operators. Ensure that the machine is user-friendly and comes with clear instructions. The Best End Cutter Machines of 2024  1. Eastman Falcon Air Example Rotary Blade: Known for its reliability and precision, Brand A's Model X end cutter machine offers a cutting-edge rotary blade mechanism, capable of handling a wide range of materials. It boasts exceptional accuracy and a user-friendly interface, making it a top choice for textile and garment manufacturers.  2. Su Lee 360H Straight Blade: Brand B's Model Y is a hot knife end cutter machine designed for efficiency and versatility. It excels in sealing edges and preventing fraying, making it ideal for industries that require sealed edges on their materials. Its sturdy construction ensures longevity.  3. Cutex TBC-50HX Example Hot Knife: Brand C's Model Z stands out for its exceptional cutting speed and efficiency. It's perfect for high-volume production environments where speed is of the essence. Despite its impressive speed, it maintains precision and accuracy in every cut. When selecting the best end cutter machine of 2024, consider the specific items you are planning on cutting, and the production process. Evaluate the cutting mechanism, cutting width, accuracy, speed, durability, safety features, and user-friendliness to make an informed decision. By choosing the right end cutter machine, you can enhance your production efficiency and achieve consistent, high-quality results in your manufacturing operations.

Investing in a reliable and advanced end cutter machine is a step towards staying competitive in your industry and meeting the demands of your customers in 2024 and beyond. Contact us today to get the machine you need!

0 Comments

Leave a Reply. |

Archives

January 2024

Categories |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

Copyright © 2024 Sewn Products Equipment Company

|

971 Airport Rd. | Jefferson, GA 30549

Local +706 367-2755 | Fax +706 367-4112 SewnProducts@SewnProducts.com |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

RSS Feed

RSS Feed