Fabric End Cutters

Increase the efficiency and versatility of your manufacturing process today with a fabric end cutter. These fabric end cutters are known for their precision and effectiveness.

Eastman Fabric End Cutters

Economy Fabric End Cutters

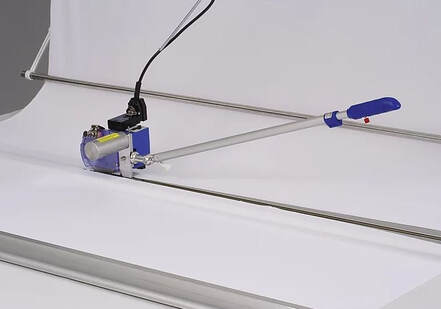

Maimin Fabric End Cutters

Fabric End Cutters Basics

Fabric End cutter machines are typically used for cutting fabric. They allow the cutting process to be fast and accurate and are often used in a workplace setting to maximize efficiency in the manufacturing process. Most end cutters are mounted on a table and have a rotary blade that is pushed across the fabric in a horizontal motion to make the cut. This blade is fitted with a guard to prevent injury. There are two main types of end cutters on the market: automatic cutters and manual cutters. Both types of end cutter have their advantages.

Automatic Fabric end cutters are amazingly fast and efficient. They are incredibly easy to operate: all you do is load the fabric and push a button. These machines have other controls to change certain parameters, such as the length of the cut and the height of the machine. Automatic end cutters are usually the higher-end option, making them less suited for those on a budget. However, despite the higher price, they do make a valuable investment in an industrial setting.

Manual Fabric end cutters are typically operated by hand, although they may still be partially automatic. Some are designed to be table-mounted, and some are not, and they are incredibly basic in comparison to the automatic end cutter. These machines tend to have a lower upfront cost, but at the sacrifice of the efficiency of automatic end cutters.

If you’re a new start up with a limited budget, the manual may be the best option. If you are looking to ramp up production, the decision between the two is a no-brainer! The automatic end cutter’s ease of use and efficiency cannot be beat!

Automatic Fabric end cutters are amazingly fast and efficient. They are incredibly easy to operate: all you do is load the fabric and push a button. These machines have other controls to change certain parameters, such as the length of the cut and the height of the machine. Automatic end cutters are usually the higher-end option, making them less suited for those on a budget. However, despite the higher price, they do make a valuable investment in an industrial setting.

Manual Fabric end cutters are typically operated by hand, although they may still be partially automatic. Some are designed to be table-mounted, and some are not, and they are incredibly basic in comparison to the automatic end cutter. These machines tend to have a lower upfront cost, but at the sacrifice of the efficiency of automatic end cutters.

If you’re a new start up with a limited budget, the manual may be the best option. If you are looking to ramp up production, the decision between the two is a no-brainer! The automatic end cutter’s ease of use and efficiency cannot be beat!