|

Heavy Duty Automatic Clothes folding machine. This is for the companies that are looking to get into a serious level of production. These are not machines for people dabbline in garment production. The STP 1000 from Thermotron can fold a huge volume with minimal human input. Optimize Your Industrial Garment ProductionMachines typically don’t differentiate between the type of garment. They only care about the size of the garment. This is why there are two main types of automatic folding machines for shirts; long-sleeve and short-sleeve.

You’ll be able to purchase a machine that has attachments which give the system the ability to cope with both long and short sleeve shirts. It’s important to look at the type of garments that are supported by the machine that you are purchasing and to look at any additional modules that will let the machine support different types of garments. To find the machines that are best suited to your set up, give us a call! We specialize in helping companies become as efficient as possible!

0 Comments

Looking at expanding your T-Shirt production? Here's our list of the top pieces of equipment to take your operation to the next level! [Best 2022] Automatic T- Shirt Folding MachineAfter your shirts have been printed, the first step to efficiency is getting them folded. Having a machine that can automatically fold the shirts. The automatic folding machine STP1000* folds ready-made garments quickly, quietly and precisely. It requires just one operator and it is designed to ideally fold T-shirts. It can be easily adjusted in order to fold various types and sizes of garments in different ways. The automatic folding machine STP1000 has a folding capacity of 5.500 garments per eight hours (the measurement was carried out at our site) and folding is achieved via 5 basic programs. The machine’s output capacity depends largely on the operator’s swiftness, the machine’s program selection and the type of garment. PV-40 Automatic T-Shirt Bagging MachineAfter the shirts have been folded, you are going to want to have your t-shirts automatically bagged. PV40 is the new automatic bagging machine for garments . The output capacity of PV40 depends on the output speed of STP1000 or on how fast the operator places the garments in the machine when the machine functions independently. The new automatic PV40 bags garments that come already folded from the automatic folding machine STP1000 in polyethylene (PE) bags in the form of an envelope. If more than one garments needs to be placed in a bag, PV40 needs to be used independently and the operator must place the garment in the machine manually. Best NT-50 Automatic T-Shirt Stacking MachineOnce the shirts are folded, bagged and ready to go, this machine will stack them for easy distribution. The NT50 is an automatic stacking machine. The NT50 stacks the already folded garments as they come from the STP1000 automatic folding machine.

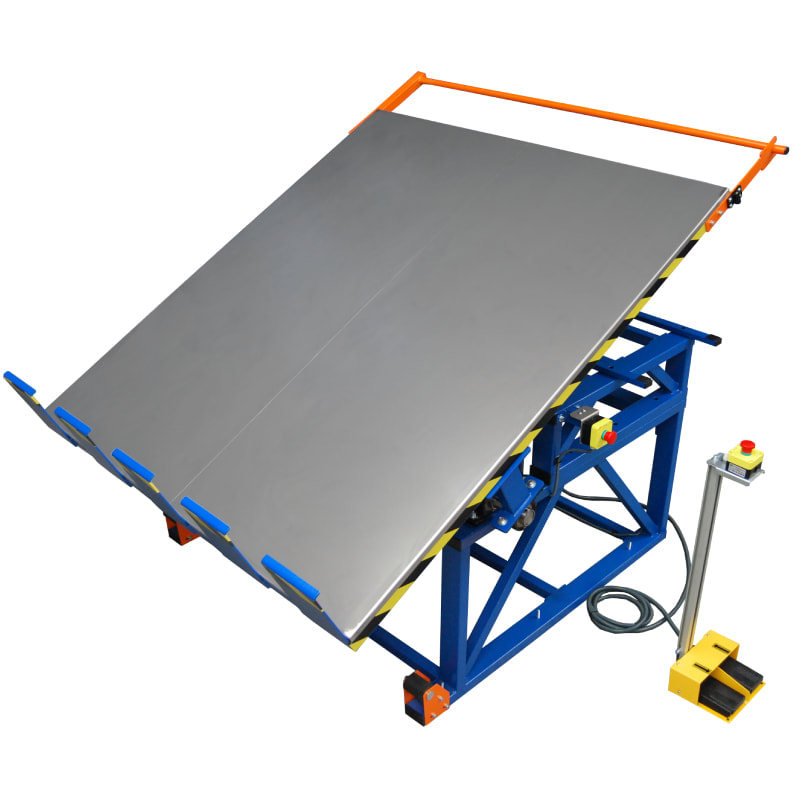

Pneumatic lift tables are excellent at making your facility safer, and more efficient! At their core, they can make your operation run more smoothly, and rely less on the brute strength of your employees, and trust the simple safe mechanisms used by thousands. Rexel SOP-1 Pneumatic Lifting TableThe Rexel SOP-1 Pneumatic Lifting Table takes the advantage of pneumatic lift tables to the next level. By allowing the top to tilt, it allows your workers to safely adjust the angle of t he product they are working on. This allows tough spots to be reached with out bending over, kneeling or having to reach in an uncomfortable manner.

Just like other pneumatic lift tables, they will also help make your factory run smoother, and have less workplace injuries. All the ups and downs, and heavy lifting will be done by efficient, easy to maintain machines. No more workmans comp claims from thrown backs! Looking to get your factory to be more efficient? Get the most out of your production with the best equipment in the textile manufacturing industry! Contact Sewn Products today to see what equipment will work for you! What is a Pneumatic Lift TableThe word pneumatic is defined as containing or operated by air or gas under pressure. Pneumatic lift tables use hollow pneumatic cylinders for their lifting power. This works by compressing the air within the cylinders to go up or down. There are a few advantages to having a pneumatic lift table over the alternatives. One of the best is that there are not flammable or toxic fluids. You will rest easy knowing your factory has one fewer safety concern. Another major advantage is that pneumatic lift tables do not need power to operate! Who's a Pneumatic Lift Table For?At Sewn Products we work with companies in many industries. They are typically involved with textile manufacturing at some level. Pneumatic Lift tables are incorporated by varied types of companies. Some common uses for Pneumatic Lift Tables are:

What's A Pneumatic Lift Table Going to Do For Your FactoryEnhanced safety and increased productivity are the main reasons people invest in pneumatic lift tables.

Enhanced Safety Not only are pneumatic lift tables non flammable and non toxic, they are great at reducing work place injuries! Once your staff is trained on how to use them, they will be thanking you. Pneumatic lift tables will cut down on acute back injuries that come up from people throwing out their back improperly lifting heavy materials or finished products. It will also reduce overall back injuries as well. When your people are able to easily raise and lower the products they are working on, this will cut down on people being hunched over for long and slowly wearing out their back! Increased Productivity Pneumatic lift tables are so simple, and so easy to use. The problems they solve are so common and every day, you will see productivity sky rocket. Instead of your people wearing themselves out and draining themselves, they will be using the pneumatic lift table. Ready to take your manufacturing to the next level? Contact Sewn Products today! We will bring our years of experience to the table to get you the equipment that's right for you! The foundation of any structure is the key element. A house can only be as good as it's foundation. A person will never rise above their character. A car is only as good as the base pieces that make it up! And it is the same thing for any piece of furniture. Furniture FoundationsThe furniture you produce can only be as good as the frame! The bedrock of modern furniture manufacturing is the zig zag spring furniture frame. The zig zag spring, also known as the no sag spring, is the common base for ottomans, sofas, and chairs. They are inexpensive, and can be easy to install, and as the name implies, they do not sag. If the frame is the foundation for your furniture, it only makes sense that a machine that assembles frames will be the foundation of a modern furniture manufacturer. Rexel NS-1 Assembling Unit for Zig-Zag SpringsIn the years that we have been helping companies optimize their textile manufacturing process, there is no machine we recommend more than the Rexel NS-1 Assembling Unit for Zig Zag Springs. It is designed for the semi-automatic assembly of furniture frames that use zig-zag springs and Rapid Clips.

Once you put the wooden frame in, you attach the zig zag springs and the machine will do the rest. The standard dimensions fit a wooden frame 1375 x 760 mm. If you have a piece of furniture that is a different size, the Rexel NS-1 can be customized to the specs you provide. Ready to take your furniture manufacturing to the next level? Find out about getting the Rexel NS-1. |

Archives

January 2024

Categories |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

Copyright © 2024 Sewn Products Equipment Company

|

971 Airport Rd. | Jefferson, GA 30549

Local +706 367-2755 | Fax +706 367-4112 SewnProducts@SewnProducts.com |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

RSS Feed

RSS Feed