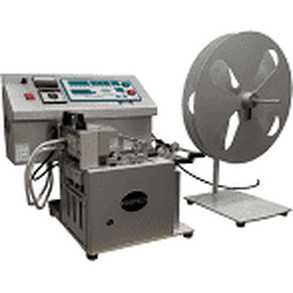

Automatic Strip Cutters: Your Secret WeaponIn the fast-paced automotive industry, precision is the name of the game. And when it comes to fabric strip cutting, an automatic strip cutter is the secret weapon you need. Introducing the Sheffield HC-530 Automatic Strip Cutting Machine, the ultimate tool for achieving top-notch finishes and revolutionizing your automotive production processes. Buckle up as we delve into the world of automatic strip cutters, where precision meets productivity.

Automatic strip cutters are the key to dominating the automotive industry with precision and efficiency. The Sheffield HC-530 Automatic Strip Cutting Machine, the ultimate tool for fabric strip cutting, will catapult your automotive projects to new heights. Say goodbye to mediocre cuts and hello to perfect precision. So buckle up, fellow car enthusiasts, and let the Sheffield HC-530 take your automotive production processes on a thrilling joyride to success!

So, why wait? Contact Sewn Products today and let our experience and dedication drive your automotive business forward. We are ready to answer your questions, provide personalized recommendations, and help you harness the precision power of the Sheffield HC-530 Automatic Strip Cutting Machine. Don't miss out on this opportunity to work with the best. Reach out now and revolutionize your fabric strip cutting game in the automotive industry. It's time to take the wheel and steer your business towards greatness!

0 Comments

Boosting Productivity in Textile Manufacturing: The Benefits of Using Roll Lifts IntroductionIn the fast-paced world of textile manufacturing, optimizing efficiency and productivity is crucial for staying competitive. One tool that can significantly enhance operations is a heavy duty roll lift. By streamlining material handling processes and reducing physical strain on workers, roll lifts offer numerous benefits that directly contribute to increased productivity in textile manufacturing. In this article, we will explore how roll lifts can revolutionize textile manufacturing and boost productivity levels. 1. Efficient Material Handling with Go Foster Roll Lifts: Go Foster Roll Lifts are specifically designed to simplify and expedite material handling tasks in textile manufacturing. Models such as the On a Roll Lifter Standard and On a Roll Lifter Low Profile by Go Foster can effortlessly lift and transport rolls of fabric, eliminating the need for manual labor. Experience efficient movement of rolls between workstations, cutting tables, and storage areas with Go Foster Roll Lifts, saving valuable time and enhancing productivity in textile manufacturing. 2. Time Savings with Go Foster Roll Lifts: Go Foster Roll Lifts, such as the Go Foster On a Roll Lifter Compact 2, offer quick and efficient operation, resulting in time savings in material handling. Minimize the time required to load, unload, or reposition rolls with the advanced features and capabilities of Go Foster Roll Lifts. Experience shorter lead times, increased output, and improved customer satisfaction in textile manufacturing, all made possible with Go Foster Roll Lifts. 3. Enhanced Safety with Go Foster Roll Lifts: Worker safety is a top priority in textile manufacturing, and Go Foster Roll Lifts prioritize safety in their design. Equipped with secure clamps or grippers, Go Foster Roll Lifts, like the On a Roll Lift Hi Rise, ensure stable and secure transportation of rolls, reducing the risk of accidents. With Go Foster Roll Lifts, workers can feel safer and more confident, focusing on their tasks without worrying about potential hazards. 4. Improved Ergonomics with Go Foster Roll Lifts: Go Foster Roll Lifts are engineered to minimize physical strain on workers, promoting better ergonomics in textile manufacturing. With the automation of lifting and movement of rolls, Go Foster Roll Lifts reduce the risk of work-related injuries caused by repetitive lifting and carrying. By investing in Go Foster Roll Lifts, textile manufacturers can create an improved ergonomic environment, enhancing worker well-being, reducing absenteeism, and maintaining a motivated and productive workforce. 5. Precise Positioning and Accuracy with Go Foster Roll Lifts: Accurate positioning of rolls is crucial for maintaining product quality and integrity in textile manufacturing, and Go Foster Roll Lifts excel in this aspect. Go Foster Roll Lifts, such as the offer adjustable arms or forks for precise positioning of rolls during loading, unloading, or placement on machinery. This level of control ensures seamless integration into various manufacturing processes, reducing errors, and enhancing overall production accuracy. Investing in roll lifts can be a game-changer for textile manufacturers seeking to increase productivity. By streamlining material handling, reducing physical strain, saving time, and enhancing safety, roll lifts optimize production processes, accelerate throughput, and improve overall efficiency in textile manufacturing. With the numerous benefits they offer, roll lifts are an amazing tool in the textile manufacturing industry. Using a roll lift will increase the productivity and safety of your organization.

When considering roll lifts for your textile manufacturing setup, it's crucial to work with a company that has experience in finding the right tools for your specific needs. Contact our experienced team at Sewn Products today. With our deep industry knowledge and expertise, we can help you identify the most suitable roll lift solutions that align with your production requirements. Maximize your productivity and take your textile manufacturing operations to new heights with the right roll lift solution. Polyester fabric is a versatile and popular choice in the apparel and garment industry, offering durability, wrinkle resistance, and vibrant color options. As an apparel and garment manufacturer working with polyester, you may wonder if using a hot knife can be used to cut polyester fabric. In this article, we will explore the feasibility of cutting polyester fabric with a hot knife, along with alternative cutting techniques to help you achieve clean and precise cuts for your polyester-based products. Can a Hot Knife Cut Polyester While a hot knife can be effective for cutting certain materials, cutting polyester with a hot knife is not always the ideal choice. Polyester fabric has a relatively low melting point compared to some synthetic materials, which can result in melted edges, fraying, and an uneven cut when using a hot knife.

The Pros and Cons of Cutting Polyester with a Hot Knife:

While a hot knife can be effective for sealing edges, cutting polyester fabric with a hot knife may lead to melting, fraying, and uneven cuts. For clean and precise results, it's recommended to use alternative cutting techniques such as scissors or rotary cutters with sharp blades, heat sealing with a heat gun, or fabric shears with a serrated edge. Choose the cutting technique that best suits your needs and consider conducting tests on scrap fabric before cutting your final project. With the right approach, you can achieve professional-looking results when cutting polyester fabric without compromising its integrity. Remember to prioritize safety while working with any cutting tools or heat sources. Take precautions, work in a well-ventilated area, and follow the manufacturer's guidelines for the tools you are using. Feel free to contact us today to help you with all of your cutting equipment needs! Ready to demolish your competition? There's two secret weapons that can help you get ahead in today's market: precision and efficiency Introducing the cutting-edge fabric cutting table – a game-changer for upholstery businesses. In this article, we'll discuss the benefits of a fabric cutting table and how it can revolutionize your upholstery manufacturing, leading to enhanced productivity, accuracy, and cost savings. Unmatched Precision for Complex Patterns Upholstery often involves intricate designs and complex patterns. With a fabric cutting table, you can achieve unmatched precision in cutting even the most intricate patterns. The sturdy and flat cutting surface, combined with advanced cutting technology, allows for clean and accurate cuts, ensuring perfect alignment and reducing material waste. Say goodbye to manual cutting errors and hello to flawless upholstery pieces that meet the highest quality standards. Increased Efficiency and Productivity Time is of the essence in upholstery manufacturing. A fabric cutting table helps streamline your production process, significantly increasing efficiency and productivity. The table's large cutting area enables you to lay out multiple fabric layers at once, allowing for batch cutting. With precise cutting guides and easy-to-use controls, you can expedite the cutting process and handle larger production volumes without compromising quality. Material Savings and Cost Efficiency

One of the significant advantages of a fabric cutting table is the ability to optimize material utilization. By arranging patterns efficiently on the cutting surface and reducing fabric waste, you can minimize material costs and maximize your profitability. The precise cutting capabilities of the table ensure that you extract the most from each fabric roll, reducing unnecessary waste and saving you money in the long run. Versatility for Various Upholstery Projects The fabric cutting table offers versatility to accommodate a wide range of upholstery projects. Whether you're working with different fabric types, thicknesses, or designs, the cutting table provides the flexibility you need. Adjustable cutting settings, such as blade speed and cutting depth, allow you to tailor the cutting process to suit specific materials, ensuring clean and accurate cuts across various upholstery projects. Enhancing Workplace Safety and Comfort Safety is paramount in any manufacturing environment. Fabric cutting tables come equipped with safety features, such as blade guards and emergency stop buttons, ensuring a safe working environment for your employees. Additionally, the ergonomic design of the table reduces operator strain and fatigue, promoting a more comfortable and efficient workflow. Embrace the cutting-edge technology of a fabric cutting table to propel your upholstery manufacturing to new heights. Experience the precision, efficiency, and cost savings that come with clean and accurate cuts. With increased productivity, optimized material utilization, and enhanced workplace safety, a fabric cutting table is an indispensable tool for upholstery manufacturers looking to stay ahead in a competitive market. Invest in a fabric cutting table today and revolutionize your upholstery production process. Contact us today to find the right machine for you! |

Archives

January 2024

Categories |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

Copyright © 2024 Sewn Products Equipment Company

|

971 Airport Rd. | Jefferson, GA 30549

Local +706 367-2755 | Fax +706 367-4112 SewnProducts@SewnProducts.com |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

RSS Feed

RSS Feed