|

Get the machines you need to ramp up your furniture manufacturing. There are machines that will automatically assemble furniture frames. That can make office chairs in a breeze. You can get a machine that will create mattresses. Or create tables. If you are serious about getting into the Furniture Manufacturing industry, we encourage you to reach out to us. You can contact us here, or you can come visit us at an event. There is one coming up in July 20-21 at the Hickory Metro Convention Center in Hickory, North Carolina. It is called t he Furniture Mnufacturing Expo 2022.

Use promo code SPEC22 to register for free as our guest!

1 Comment

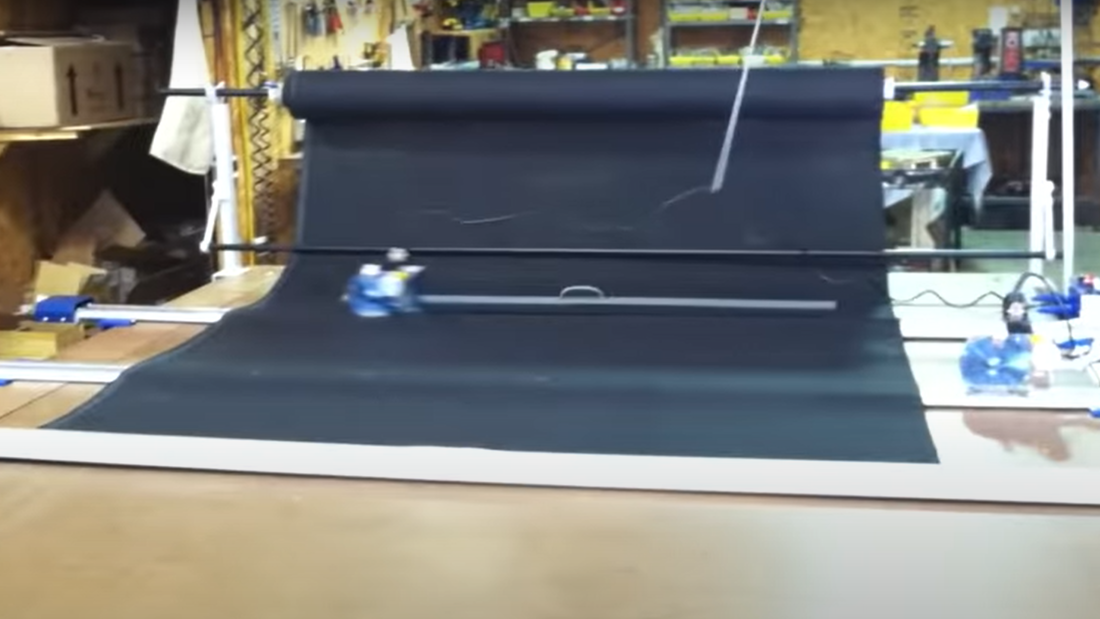

There are a lot of ways to scale a fabric manufacturing plant. You can: - Rent a bigger space - Get more employees - Work longer hours These are difficult, time-consuming measures, though, with minimal guarantee of success. The most successful companies in the industry work smarter to get more done. How? With better tools and technology! Using our track end cutters is one of the best ways to scale up a fabric manufacturing if you work with large pieces of fabric. With our variety of cutters, you are sure to find the machine that works best for your operation. These cutters are typically mounted on a table and are either manual or automatic. Manual cutters sit on a predefined track while automatic cutters are programmed to cut along precise lines. Both of these types of machines dramatically cut down on user error. Depending on your operation, you can use multiple machines as in the picture shown to have greater effect!

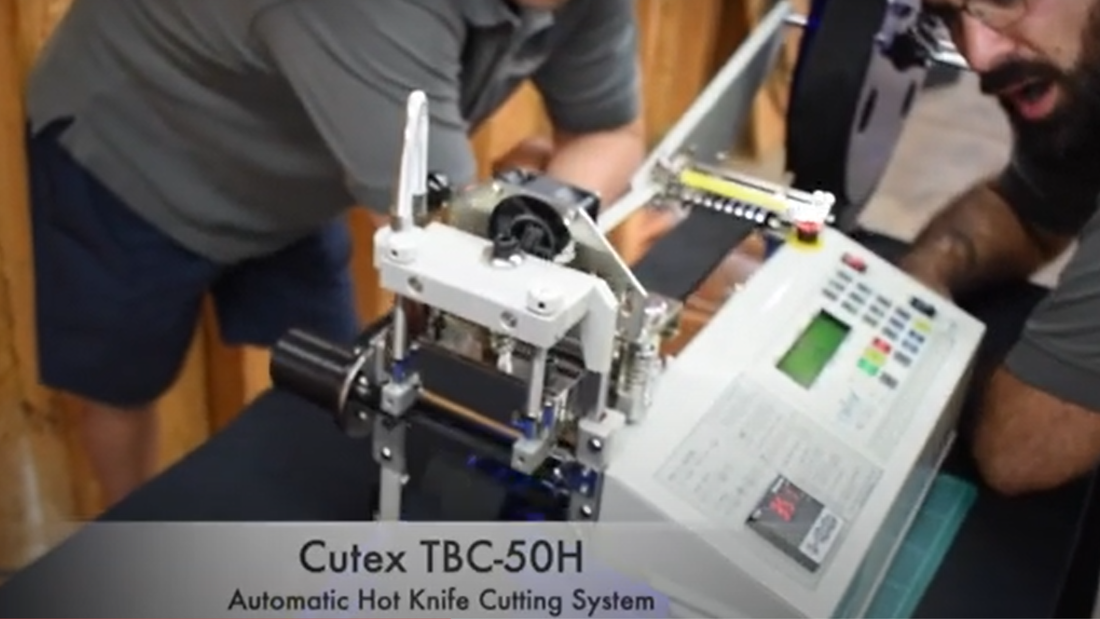

Give us a call today and we’ll set you up with the best machine for your business! The Old Way to Cut Fabric Strips and Seal the EdgesCutting and sealing fabric strips used to be a two-man operation: one wielded the ruler and scissors to carefully measure out and cut strips of fabric, and the other sealed the edges of the fabric strips with a lighter. There are so many ways this could go wrong! 1. The ruler is difficult to line up perfectly, especially if the worker is trying to move fast. 2. The scissors could be too dull to cut with and mess up the fabric. 3. The scissors could be too sharp and could harm the worker. 4. A lighter in a warehouse. Need I say more? There is a better way! Scissors, rulers, and lighters are so primitive compared to this beauty! The TBC-50H Strip Cutter will perfectly measure, cut, and seal as many fabric strips as you need, every single time. Save time, manpower, and potential safety hazards with this excellent machine.

It’s quick. It’s easy. It’s accurate! Discover the best way to cut fabric strips. It's quick. It's easy. It's accurate! Efficiency in a Factory. It can lead to growth. Explosive growth! Make your operation more efficient. You can have one operator do two jobs at once (unloading and loading). Stackers can be configured to any existing or new system.

Fusing Machines are used in the garment industry to fuse a material capable of being fused to a base fabric through the process of pressure, heat, and time. The fused material should have acceptable strength, the ability to stand continuous wash, or any fabric treatment This process is excellent to add value to any fabric that needs to be bonded to others. Having an automatic stacking such as the Automatic Stacker System SYC from Martin Group. This amazing tool will help your operation become more efficient by allowing a single operator to load and unload textiles!

With so much work to do and only so much space to do it in, sometimes looking for a bigger warehouse isn’t the best option for your business. The better thing to do would be to find tools and tables that work efficiently and utilize the space you have in the best way possible. Our top-of-the-line air flotation tables can help you get the job done right without costing you space and time. Unlike our other spreading tables, the Phillocraft Pow-R-Pax Air-Tex Table and Philocraft Pow-R-Pax Grip-Tex Table offer the latest innovations in air table technology, utilizing highly automated facilities to produce a superior product. Trust us—these are not your ordinary worktables! These tables provide the optimal use of your spreading and cutting equipment. In the Phillocraft Air-Tex table, air is forced up through small holes in the surface of the top by means of a quiet, specially engineered filtered air system. A boundary layer of air forms, allowing effortless movement of heavy materials over the table surface. The Phillocraft Grip-Tex table is a modern air-suction table, with a patented manifold core top. Air suction provides unequaled power to stabilize or compress. With these two types of tables, cutting and spreading will move along at a fast pace, and paired with the right equipment, it’ll cut down on the amount of space taken up and the number of workers required to get the job done!

Depending on the needs of your business, we can help you find the exact table you’re looking for. Contact us today for more information! |

Archives

January 2024

Categories |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

Copyright © 2024 Sewn Products Equipment Company

|

971 Airport Rd. | Jefferson, GA 30549

Local +706 367-2755 | Fax +706 367-4112 SewnProducts@SewnProducts.com |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

RSS Feed

RSS Feed