|

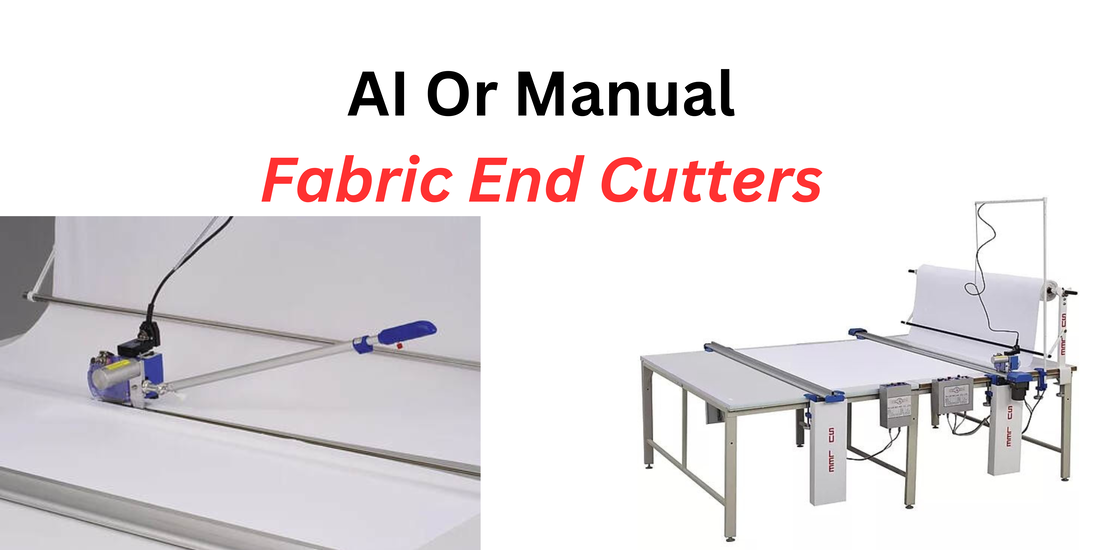

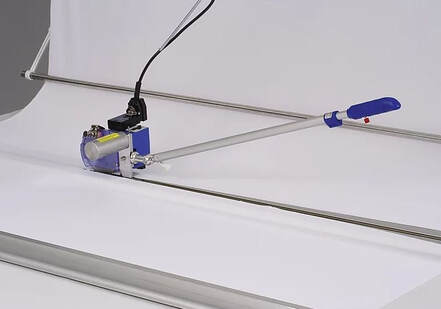

Imagine you're in a world where making clothes is like a puzzle. You need to cut fabric pieces just right to fit together. Here's the twist: you can use two types of machines to do the cutting - one you control by hand, and the other that goes on its own. It's a bit like choosing between a hands-on craft and a futuristic gadget. Let's dig into these choices! We're about to find out which one fits your needs better. So, let's dive into the world of manual and automatic fabric cutters. Alright... The stage is set. Let's dive int Automatic Or Manual Fabric End Cutter The main difference between an automatic fabric end cutter and a manual end cutter lies in how they operate and the level of automation they offer in the cutting process. Here's a breakdown of the distinctions between the two: 1. Automation Level: - Automatic Fabric End Cutter: An automatic fabric end cutter is equipped with advanced technology that enables it to operate independently with minimal human intervention. These machines are designed to measure, position, and cut fabric accurately without the need for constant manual adjustments. They often include computer-controlled systems that ensure precision and consistency. - Manual End Cutter: A manual end cutter, as the name suggests, requires human effort to operate. Operators use these cutters to measure, position, and cut fabric manually. While manual end cutters can still provide accurate cuts, they rely more on the operator's skill and attention to detail 2. Precision and Accuracy: - Automatic Fabric End Cutter: Automatic end cutters are known for their high precision and accuracy. They are designed to cut fabrics with minimal deviation, ensuring consistent results. Advanced sensors and technology contribute to their precise cutting capabilities. - Manual End Cutter: Manual end cutters can also deliver precise cuts, but the level of precision depends on the operator's skill and experience. Human factors, such as fatigue and variations in manual measurements, can influence the accuracy of cuts 3. Speed and Efficiency: - Automatic Fabric End Cutter: Automatic end cutters are generally faster and more efficient in terms of cutting speed. They can process fabrics quickly and consistently, making them suitable for high-volume production environments. - Manual End Cutter: Manual end cutters might have a slower cutting pace compared to their automatic counterparts, as they rely on human manipulation and measurements. This can lead to variations in cutting speed and efficiency. 4. Workload and Labor: - Automatic Fabric End Cutter: Automatic end cutters require less direct human involvement. Operators typically load the fabric onto the machine, set parameters, and initiate the cutting process. This reduces the need for constant operator attention and can free up labor for other tasks. - Manual End Cutter: Manual end cutters require operators to be present throughout the cutting process. The operator needs to measure, position, and execute cuts manually. This can be more labor-intensive, especially for prolonged cutting sessions. 5. Consistency: - Automatic Fabric End Cutter: Automatic end cutters provide a higher level of consistency in cuts due to their automated nature. They reduce the potential for human error and variations in cutting quality. - Manual End Cutter: The consistency of cuts with manual end cutters depends on the operator's skill, attention, and physical factors. Variability in manual cuts might lead to slightly less consistent results. Automatic fabric end cutters offer a higher degree of automation, precision, speed, and efficiency compared to manual end cutters. However, manual end cutters can still be effective for smaller-scale operations and situations where hands-on control is preferred. The choice between the two depends on factors such as production volume, cutting precision requirements, labor availability, and budget considerations. To get the most out of your end cutter - give us a call! We help companies like yours find the machine that meets their needs!

0 Comments

|

Archives

January 2024

Categories |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

Copyright © 2024 Sewn Products Equipment Company

|

971 Airport Rd. | Jefferson, GA 30549

Local +706 367-2755 | Fax +706 367-4112 SewnProducts@SewnProducts.com |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

RSS Feed

RSS Feed