|

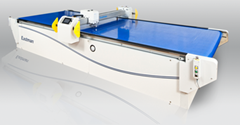

How do you cut a material that is supposed to be knife and bullet proof? With the right tools, it's not actually that complicated. Cutting through kevlar with the right tool is very doable. The Old Fashioned WayThe first way to cut Kevlar is by brute force. The two primary ingredients in this process is going to be you, and then the other piece is the tool that you use. You are going to need something hard enough to cut the material. Here are some of the best tools available! Manual Ways to Cut KevlarThere are many ways to cut Fiber glass and Kevlar by hand. The most popular way of cutting fiberglass, crazy as it seems, is scissors. The best scissors that I have found are Kretzer Germany Steel Scissors. This brand last for a very long time due to its high quality steel, plus Kretzer designed serrated blades specifically for fiberglass industry. This designed blades enables the operator to cut the material more efficiently while keeping the cut quality high. Motorized Tools to Cut KevlarDepending on your application there are different motorized tools that are designed for the Fiberglass industry. Here are the different power tools that I would recommend depending on the facility’s application (boat hauls, windmills, etc.): Trimming single or every low plyEastman Buzzaird (pneumatic) The Eastman Buzzard is a pneumatic driven rotary shear that reaches up to 20,000 RPM with high torque. This machine is designed for trimming single (or low) ply of material. You can see what I mean by trimming when you look at the video in the link above. Rasor Optima 702 (electric- 110V or 220V)Rasor Optima 702/703 is an electrically driven rotary shear. It is a high torque motor, so it can power through really tough material. Rasor Zero702 (Battery)Rasor Zero 702 is a battery operated rotary shear. It is the most powerful and robust battery rotary shear on the market. This machine has variable speed and it cuts fiberglass and kevlar like butter. How to Cut ALOT of KevlarMultiply CuttingIf you are cutting multiple layers or cutting kevlar and fiberglass on a table, I would recommend Straight Knife to cut your kevlar. Eastman Brute is the heavy duty version of the Eastman Straight knife. It has more robust motor to add higher torque with the same RPM (3600 RPM). Having this type of cutting machine allows you to cut more material at the same time, while keeping the fiberglass away from the moving parts on the machine besides the knife. Fiberglass is a really abrasive material, so if it gets inside the machine (especially a moving part), it will bog down your machine and eventually break it. Check on the video in the link about to see what I mean by stack cutting or multiply cutting. AutomatedThe best way to cut fiber glass automatic is by two ways: Cut to length machine or fully automated cutting machine. Automatic Cutting Machine The most efficient way to cut fiber glass and kevlar. This machine cuts fiberglass at amazing speeds with incredible accuracy. This system is designed to cut out any 2D shape on any material loaded into the bed of the cutter. They do have systems that also convey the material forward to make it even more efficient. Not only is the machine fast and accurate ,but it is so good for cutting fiberglass (depending on what type) because it uses a “crush style” cutting system to cut out the patterns. This helps certain fiberglass (not all) material from not fraying. These uses allow you to mark and punch the material also if needed. Cut to Length If your operation just need your material to be cut into squares or rectangles, than the cut to length machine is the correct machine for your application. The machine is designed to unwind a roll of material and measure the material to length. Once it measure the material to length it performs a cross cut on the fiberglass material. Then you have a perfectly measured cut to length pc of material. This machine is fully customizable; slitters, conveyor belt, rerolling attachment and etc. Once you are equipped with the right tools, the actual how to of cutting kevlar is pretty straight forward. We have been helping companies find the right tools for the job for years. If you are looking at getting into cutting fiber glass or kevlar, we would be happy to help you find the machine that suits you!

1 Comment

|

Archives

January 2024

Categories |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

Copyright © 2024 Sewn Products Equipment Company

|

971 Airport Rd. | Jefferson, GA 30549

Local +706 367-2755 | Fax +706 367-4112 SewnProducts@SewnProducts.com |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

RSS Feed

RSS Feed