|

The T-Shirt Auto-Catcher – a game-changing machine for screen printing. If you're in the world of screen printing, you'll want to learn why this machine is a must-have to boost efficiency and save on costs. Why You Need the Auto-Catcher:

Screen printing is both an art and a science, and the Auto-Catcher perfectly balances both. This machine is designed to save you time and increase productivity by automating the catching and stacking process. Say goodbye to manual labor and hello to streamlined efficiency. Unleash Your Screen Printing Potential: The Auto-Catcher doesn't just catch garments; it catches opportunities. By automating the repetitive tasks, it frees up your workforce to focus on what truly matters – improving your strategic workflow and delivering top-notch products. A Path to Efficiency and Savings: The Auto-Catcher isn't just a machine; it's a key to your screen printing success. Embrace the future of screen printing, unlock efficiency, and enjoy substantial savings with the Auto-Catcher. It's time to revolutionize your operations – get in touch with us today and embark on a journey to a more efficient and profitable screen printing business.

0 Comments

In the fast-paced world of manufacturing, efficiency is paramount. Every minute counts, and every process must be optimized for productivity. Phillocraft Production Tables step into this arena as game-changers, redefining the way textile manufacturers approach their production processes. Efficiency at the Core: Phillocraft Production Tables are designed to maximize workflow efficiency. With more workspace, durable construction, and well-thought-out design, these tables offer a streamlined production process. Downtime is reduced, productivity soars, and you can meet your deadlines with ease Consistency in Every Cut: Consistency is the hallmark of quality manufacturing, and Phillocraft Production Tables excel in maintaining material alignment. Whether you're working with delicate textiles or heavy-duty materials, these tables ensure uniform layering. This results in consistently high-quality end products, eliminating costly rework and errors. Built to Last: In an industrial setting, equipment durability is non-negotiable. Phillocraft Production Tables are constructed from top-quality materials, ensuring they can withstand the daily rigors of your manufacturing environment. Say goodbye to the worries of equipment wear and tear, and count on Phillocraft for tables built to last. They are also built to be flexible to meet the needs of your manufacturing operation. Phillocraft offers Kits such as Widening Kit, Expansion Module, Blower Kits, and Air Conversion Kit Experience Excellence with Phillocraft:

Choosing Phillocraft means choosing a trusted name in the industry known for its commitment to quality, precision, and durability. Elevate your production processes with our Production Tables, and unlock a new level of efficiency and precision in your manufacturing business. Invest in Phillocraft Production Tables today and discover a world of superior manufacturing solutions. Reach out to us today to find the right table for your manufacturing needs! When it comes to optimizing your production processes, one name stands out: Phillocraft. In this guide, we'll explore how Phillocraft Tables can revolutionize your production. 1. Phillocraft Fabric Spreading Tables: Precision Unleashed In a world where every cut matters, Phillocraft Fabric Spreading Tables offer a stable and level surface that's the key to precision. Perfect for textiles, these tables solve the problem of inaccuracies in cuts and material waste. With Phillocraft, you'll experience precise cuts that minimize rework and discarded materials. 2. Production Tables: Streamline Your Workflow Efficiency is the heartbeat of manufacturing in 2024. Phillocraft Production Tables are designed to optimize your workflow, making inefficient processes a thing of the past. The Phillocraft Pow-R-Pax Production/Cutting Table can be adjusted to the exact size that you need. Say goodbye to unnecessary downtime and embrace seamless production. 3. Spreading Tables: Consistency Redefined

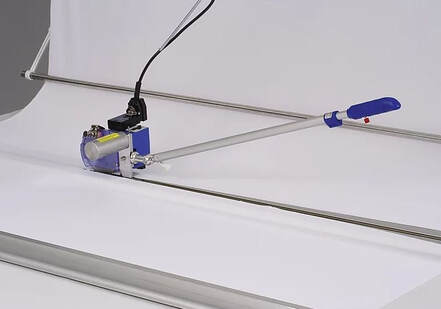

Consistency is your signature in the market, and Phillocraft Spreading Tables ensure it's never compromised. These tables excel in maintaining material alignment, solving the challenge of material misalignment and inconsistent product quality. Your clients will appreciate the uniformity of your offerings. 4. Industrial Cutting Tables: Durability Meets Dependability In an industrial setting, equipment durability is paramount. Phillocraft Industrial Cutting Tables are built to withstand the rigorous demands of daily use. Solve the problem of equipment wear and tear with tables that offer long-lasting performance and reliability, ensuring you meet your production goals without disruptions. You can also find parts and kits to maintain or adjust your Phillocraft Production table as you need. 5. Finding Your Perfect Size: Flexibility That Fits Your Workspace Workspace constraints can limit your potential, but not with Phillocraft. With a range of table sizes, you can choose the one that fits your specific space and production needs. It's the flexibility that addresses the challenge of size limitations without compromising on efficiency. Experience Excellence with Phillocraft in 2024 2024 is the year of elevating your production efficiency, and Phillocraft Tables are your partners in achieving that goal. With impeccable craftsmanship, a variety of sizes, and a commitment to quality, Phillocraft sets the stage for a year of increased precision and productivity. Invest in Phillocraft Tables for 2024 and unlock a new level of efficiency and precision in your textile or manufacturing business. Explore our range of tables and find the perfect fit for your evolving needs. Welcome to a year of superior cutting and spreading solutions – welcome to Phillocraft! If you need help finding the right table, contact us today! If you're in the market for an end cutter machine in 2024, you're in luck. These machines have evolved significantly over the years, offering improved performance, precision, and efficiency. Whether you're in the textile, apparel, or manufacturing industry, choosing the right end cutter machine is crucial for streamlining your operations. In this guide, we'll explore the key factors to consider and provide recommendations for the best end cutter machines in 2024. 2. Cutting Width: The cutting width determines the maximum size of the materials you can work with. You are going to want to make sure the machine you choose can handle the width of the materials you typically use in your production process. 3. Accuracy and Precision: Look for an end cutter machine that offers high accuracy and precision in cutting. Clean, precise cuts are essential for minimizing material waste and achieving consistent results. 4. Speed and Efficiency: Efficiency is a key consideration for any manufacturing process. The cutting speed of the machine can significantly impact your production rates. Choose a machine that balances speed with accuracy to meet your requirements. 5. Durability: A durable machine is an investment that pays off in the long run. Consider the build quality, materials, and construction of the machine to ensure it can withstand regular use in an industrial setting. 6. Safety Features: Safety should always be a top priority. Look for machines that come equipped with safety features such as protective guards, emergency stop buttons, and safety sensors to prevent accidents. 7. User-Friendliness: An easy-to-use interface and intuitive controls can save you time and reduce the learning curve for your operators. Ensure that the machine is user-friendly and comes with clear instructions. The Best End Cutter Machines of 2024  1. Eastman Falcon Air Example Rotary Blade: Known for its reliability and precision, Brand A's Model X end cutter machine offers a cutting-edge rotary blade mechanism, capable of handling a wide range of materials. It boasts exceptional accuracy and a user-friendly interface, making it a top choice for textile and garment manufacturers.  2. Su Lee 360H Straight Blade: Brand B's Model Y is a hot knife end cutter machine designed for efficiency and versatility. It excels in sealing edges and preventing fraying, making it ideal for industries that require sealed edges on their materials. Its sturdy construction ensures longevity.  3. Cutex TBC-50HX Example Hot Knife: Brand C's Model Z stands out for its exceptional cutting speed and efficiency. It's perfect for high-volume production environments where speed is of the essence. Despite its impressive speed, it maintains precision and accuracy in every cut. When selecting the best end cutter machine of 2024, consider the specific items you are planning on cutting, and the production process. Evaluate the cutting mechanism, cutting width, accuracy, speed, durability, safety features, and user-friendliness to make an informed decision. By choosing the right end cutter machine, you can enhance your production efficiency and achieve consistent, high-quality results in your manufacturing operations.

Investing in a reliable and advanced end cutter machine is a step towards staying competitive in your industry and meeting the demands of your customers in 2024 and beyond. Contact us today to get the machine you need! In the world of industrial manufacturing, precision and efficiency are the twin pillars of success. If you're in search of the perfect production table to take your manufacturing process to the next level, look no further than Philocraft Production Tables. In this article, we'll explore the exceptional features and advantages of Philocraft production tables, designed to transform your workspace, enhance productivity, and ensure impeccable results. Customized for Your Needs One size does not fit all in the industrial world, and Philocraft understands this better than most. Their Pow-R-Pax Production/Cutting Tables offer the ultimate in customization. You have the power to tailor the size of your table to your exact requirements. Whether you need a compact workstation for intricate tasks or a vast surface to accommodate large fabric rolls, Philocraft ensures your table aligns perfectly with your production demands. This level of customization is invaluable, allowing you to create a workspace that optimally suits your workflow. Ergonomics at the Forefront

In any industrial setting, ergonomics is not just a luxury; it's a necessity. Philocraft's Workshop Table sets the standard for ergonomics. With a standard height range of 33" to 37", it's designed with operator comfort in mind. Fatigue is reduced, productivity is boosted, and safety is enhanced when your team works in a comfortable and well-aligned environment. For those seeking even more flexibility, Philocraft offers an optional height adjustment, ranging from 26-3/8" to 43-3/4". This adaptability ensures that your production table is tailored not only to your tasks but also to the physical well-being of your team. Durability and Precision Combined Philocraft Production Tables are built to last. Crafted with durability in mind, these tables can withstand the rigors of industrial use, ensuring your investment remains reliable for years to come. But it's not just about durability; it's also about precision. These tables are engineered to maintain accurate alignment and tension control, effectively eliminating fabric distortion. In a world where precision matters, Philocraft ensures your fabric manufacturing reaches new heights of excellence. Philocraft Production Tables are more than just tables; they're the cornerstone of a productive and efficient workspace. With customization, ergonomics, durability, and precision at the forefront, Philocraft empowers your team to achieve more and do it with impeccable accuracy. If you're ready to revolutionize your manufacturing process, Philocraft Production Tables are your answer. Invest in the best and watch your productivity soar. Contact Philocraft today to explore the perfect table for your needs and take your industrial manufacturing to a whole new level. Selecting the right industrial spreading table can make all the difference in streamlining your production process and maximizing productivity. When it comes to top-tier spreading tables, one name stands out - Phillocraft. Phillocraft's industrial spreading tables are renowned for their quality, reliability, and cutting-edge features. With a range of table sizes and capacities to choose from, they can seamlessly accommodate the unique needs of your fabric manufacturing operation. These tables are designed with durability in mind, ensuring they withstand the rigors of an industrial setting, making them a long-lasting investment. Tailoring Your Workspace: Customizable Table Sizes and Heights by PhillocraftWhen it comes to choosing the right industrial spreading table for your fabric manufacturing needs, size and capacity are paramount considerations. Phillocraft understands that one size does not fit all. With the Phillocraft Pow-R-Pax Production/Cutting Tables, you have the flexibility to customize the table to your exact size requirements, ensuring it seamlessly accommodates the dimensions of your fabric rolls. This level of customization is invaluable for tailoring your workspace to your unique production demands. Additionally, for those seeking versatility in table height, the Phillocraft Workshop Table offers a standard height range of 33" to 37". If you require further adjustment, an optional height range from 26-3/8" to 43-3/4" is also available. With Phillocraft, you have the power to choose a spreading table that perfectly aligns with your production goals and ergonomic preferences. What truly sets Phillocraft apart is their commitment to precision and efficiency. Their spreading tables are engineered to maintain accurate alignment and tension control, preventing fabric distortion and ensuring consistently flawless results. With adjustable height settings for ergonomic comfort and safety features that prioritize your operators' well-being, Phillocraft offers an all-encompassing solution for fabric manufacturers. When you're ready to elevate your fabric manufacturing, choose Philocraft for a superior spreading table that delivers on its promises. You can contact us today to get started on your Phillocraft table!

Whether you're producing clothing, upholstery, or anything that needs fabric, precision and efficiency are essential. A Fabric Strip Cutting Machine can make all the difference. In this blog post, we'll discuss the benefits of a Fabric Strip Cutting Machine and how it can be a game-changer for you! The Power of Strip Cutting PrecisionPrecision is so important in textile manufacturing, especially when it comes to creating fabric strips. A Fabric Strip Cutting Machine is designed to excel in this department. It can consistently and accurately cut fabric into strips of your desired width. This precision ensures uniformity in your products, which is crucial for quality and fit EfficiencyTime is money, and in manufacturing, every second counts. A Fabric Strip Cutting Machine is engineered to optimize efficiency. It can swiftly process rolls of fabric, converting them into strips in a fraction of the time it would take with manual methods. This speed and efficiency translate to cost savings and increased production capacity. Versatile Strip CuttingTextile manufacturers often work with a variety of fabrics, each with its unique characteristics. The versatility of a Fabric Strip Cutting Machine shines here. These machines can handle a wide range of fabric types, from delicate silks to heavy denims. With adjustable settings and precise cutting mechanisms, you have the flexibility to cut strips from various textiles without compromising quality. Minimizing Material WasteWaste reduction is not just about saving money; it's also about sustainability. A Fabric Strip Cutting Machine minimizes material wastage by optimizing the use of fabric rolls. The precise cuts mean you throw away less material, contributing to a greener and more environmentally responsible manufacturing process.

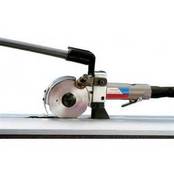

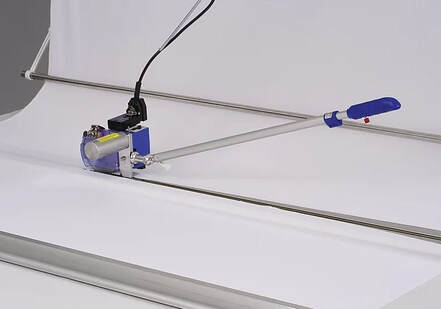

In the competitive realm of textile manufacturing, investing in a Fabric Strip Cutting Machine is an excellent move. With its precision, efficiency, versatility, and safety features, it can elevate your production process to new heights. Quality, speed, and cost-effectiveness are no longer distant goals but achievable benchmarks with the right equipment by your side. If you're ready to unlock the full potential of your textile manufacturing, give us a call! We have helped many companies find the perfect machine. In the world of textile manufacturing, precision and efficiency are the cornerstones of success. Whether you're producing apparel, upholstery, or any other textile-based product, the quality of your cuts plays a vital role in the final product. This is where a Fabric End Cutter comes in, offering both precision and efficiency. In this article, we're going to dive into the pros of a Fabric End Cutter, and how it can revolutionize your textile production, leading to higher quality products, reduced material waste, and an increase in productivity. The Power of Precision CuttingPrecision is the name of the game in textile manufacturing, and a Fabric End Cutter is engineered to excel in this department. Whether you're working with delicate fabrics or heavy-duty materials, these cutting machines are designed to provide clean and precise cuts consistently. The result? Perfectly aligned pieces that fit seamlessly into your production process, ultimately enhancing the overall quality of your textile products EfficiencyTime is money, and textile manufacturers understand this all too well. A Fabric End Cutter is your secret weapon to optimizing efficiency. These machines are built to handle high volumes of cutting with speed and accuracy. With a Fabric End Cutter, you can bid farewell to the tediousness of manual cutting and say hello to a streamlined process that significantly reduces production time, translating into cost savings and increased output Flexible Fabric Cutting Solutions Textile manufacturers often work with a diverse range of fabrics, from fine silks to heavy denim. The beauty of a Fabric End Cutter lies in its versatility. These machines are equipped to handle various fabric types and thicknesses. With adjustable settings and blades designed for specific materials, you have the flexibility to switch between different textiles seamlessly, eliminating the need for multiple cutting tools. Minimize Material WasteWaste not, want not. A Fabric End Cutter is your ally in reducing material wastage. Through precise cutting and efficient use of fabric, you'll find that you're tossing less material into the scrap bin. This not only saves you money on materials but also contributes to a more sustainable and environmentally friendly manufacturing process. In the competitive world of textile manufacturing, investing in a Fabric End Cutter is a strategic move. With its precision, efficiency, versatility, and safety features, it can elevate your production process to new heights. Quality, speed, and cost-effectiveness are no longer distant goals but achievable benchmarks with the right equipment by your side. If you're ready to unlock the full potential of your textile manufacturing, and need help finding the perfect Fabric End Cutter, reach out to Sewn Products. We have been helping companies improve their efficiency and production for years!

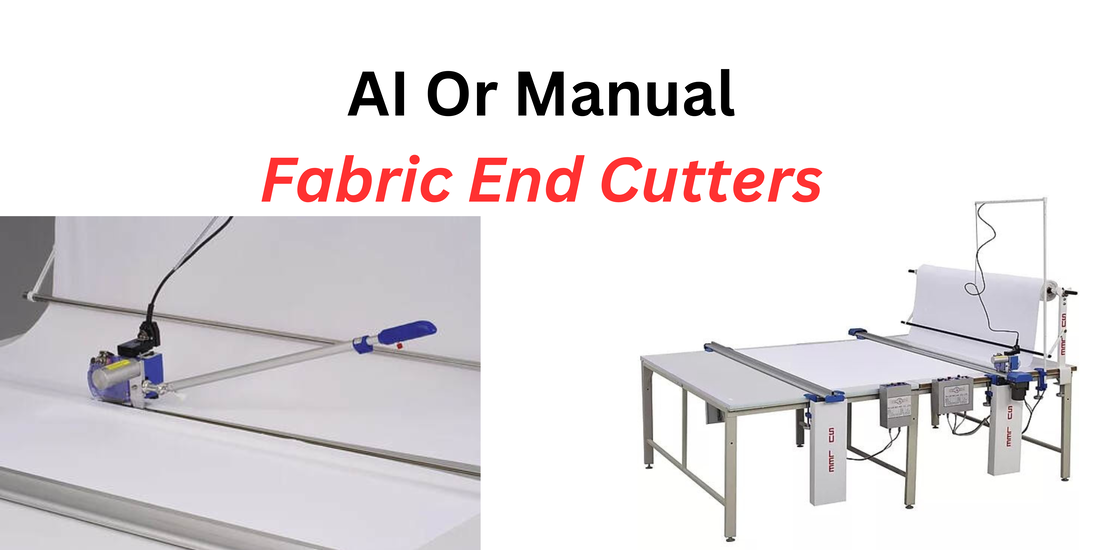

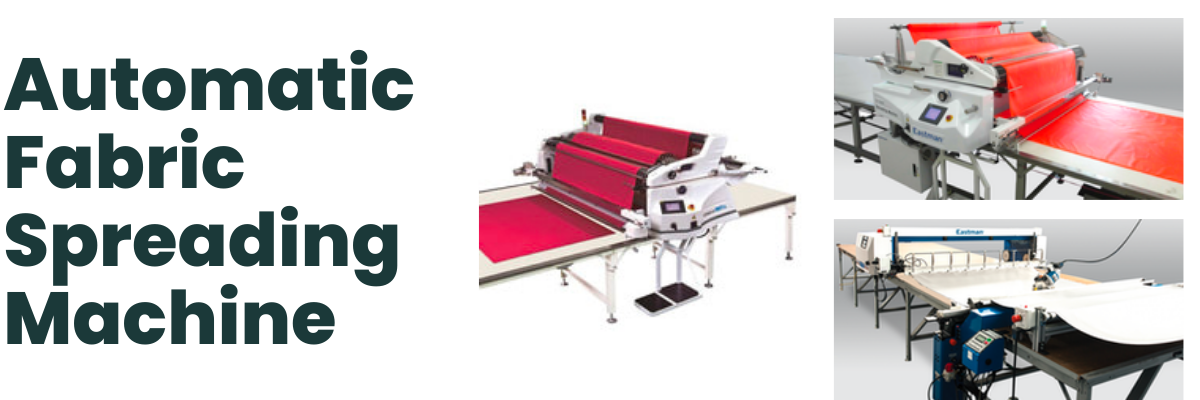

Imagine you're in a world where making clothes is like a puzzle. You need to cut fabric pieces just right to fit together. Here's the twist: you can use two types of machines to do the cutting - one you control by hand, and the other that goes on its own. It's a bit like choosing between a hands-on craft and a futuristic gadget. Let's dig into these choices! We're about to find out which one fits your needs better. So, let's dive into the world of manual and automatic fabric cutters. Alright... The stage is set. Let's dive int Automatic Or Manual Fabric End Cutter The main difference between an automatic fabric end cutter and a manual end cutter lies in how they operate and the level of automation they offer in the cutting process. Here's a breakdown of the distinctions between the two: 1. Automation Level: - Automatic Fabric End Cutter: An automatic fabric end cutter is equipped with advanced technology that enables it to operate independently with minimal human intervention. These machines are designed to measure, position, and cut fabric accurately without the need for constant manual adjustments. They often include computer-controlled systems that ensure precision and consistency. - Manual End Cutter: A manual end cutter, as the name suggests, requires human effort to operate. Operators use these cutters to measure, position, and cut fabric manually. While manual end cutters can still provide accurate cuts, they rely more on the operator's skill and attention to detail 2. Precision and Accuracy: - Automatic Fabric End Cutter: Automatic end cutters are known for their high precision and accuracy. They are designed to cut fabrics with minimal deviation, ensuring consistent results. Advanced sensors and technology contribute to their precise cutting capabilities. - Manual End Cutter: Manual end cutters can also deliver precise cuts, but the level of precision depends on the operator's skill and experience. Human factors, such as fatigue and variations in manual measurements, can influence the accuracy of cuts 3. Speed and Efficiency: - Automatic Fabric End Cutter: Automatic end cutters are generally faster and more efficient in terms of cutting speed. They can process fabrics quickly and consistently, making them suitable for high-volume production environments. - Manual End Cutter: Manual end cutters might have a slower cutting pace compared to their automatic counterparts, as they rely on human manipulation and measurements. This can lead to variations in cutting speed and efficiency. 4. Workload and Labor: - Automatic Fabric End Cutter: Automatic end cutters require less direct human involvement. Operators typically load the fabric onto the machine, set parameters, and initiate the cutting process. This reduces the need for constant operator attention and can free up labor for other tasks. - Manual End Cutter: Manual end cutters require operators to be present throughout the cutting process. The operator needs to measure, position, and execute cuts manually. This can be more labor-intensive, especially for prolonged cutting sessions. 5. Consistency: - Automatic Fabric End Cutter: Automatic end cutters provide a higher level of consistency in cuts due to their automated nature. They reduce the potential for human error and variations in cutting quality. - Manual End Cutter: The consistency of cuts with manual end cutters depends on the operator's skill, attention, and physical factors. Variability in manual cuts might lead to slightly less consistent results. Automatic fabric end cutters offer a higher degree of automation, precision, speed, and efficiency compared to manual end cutters. However, manual end cutters can still be effective for smaller-scale operations and situations where hands-on control is preferred. The choice between the two depends on factors such as production volume, cutting precision requirements, labor availability, and budget considerations. To get the most out of your end cutter - give us a call! We help companies like yours find the machine that meets their needs! Welcome, fellow garment cutters, to the world of precision and efficiency in fabric spreading! Fabric spreading tables play a pivotal role in the cutting room, ensuring accurate alignment and a seamless cutting process. Today, we explore how fabric spreading tables revolutionize the cutting game for the elite garment cutters. Buckle up and get ready for an adventure that combines efficiency, productivity, and of course, the ever-important health benefits. 1. Reduced Physical Strain: As a dedicated garment cutter, you know that long hours of standing and repetitive movements are the norm. But fear not! Fabric spreading tables come with an ergonomic twist. With an adjustable height feature, we can set the table at our perfect level, avoiding the dreaded back strain and musculoskeletal disorders. Goodbye, discomfort - hello, perfect posture! Now we can focus on our precise cutting skills without worrying about the physical burden. 2. Enhanced Efficiency with Automatic Fabric Spreading Machines: Listen up, team - efficiency is our middle name! And we've got a secret weapon: automatic fabric spreading machines! These babies take fabric spreading to a whole new level. They're fast, precise, and can handle those large fabric rolls like pros. With fabric spreading tables teaming up with automatic machines, we've got a flawless workflow. Say goodbye to manual handling and hello to streamlined processes. We're taking on those high-volume orders like champions! 3. Improved Health and Comfort with Manual Fabric Spreading Machines: Not all heroes wear capes, and not all fabric spreading machines are automatic. Some of us prefer the hands-on approach. But don't worry, we've got your back! Literally! With the right manual fabric spreading machine, we're talking comfort and well-being all day long. The smooth surface keeps fabric rolls in place, and the non-slip magic is real! Say hello to reduced fatigue and minimized physical strain - we're unstoppable! There you have it, fellow garment cutters - the true power of fabric spreading tables! These tables are unsung heroes in the cutting room. They bring efficiency, precision, and enhanced health benefits to our world. Whether we're working with automatic machines or embracing the manual touch, fabric spreading tables are our trusted sidekicks. Embrace the full potential of these incredible tools. With fabric spreading tables on our team, we're cutting our way to success in the world of fashion! Contact us today to get started on your next fabric spreading table!

|

Archives

January 2024

Categories |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

Copyright © 2024 Sewn Products Equipment Company

|

971 Airport Rd. | Jefferson, GA 30549

Local +706 367-2755 | Fax +706 367-4112 SewnProducts@SewnProducts.com |

- Home

-

Products

- Air Flotation Tables

- Automatic Folding Machines

- Automatic Stacking Equipment

- Automatic Strapping and Banding Machines

- Band Knife Machines

- Bias Cutting Systems

- Blind Cutting Tables

- Collarette Cutters

- Cuff, Collar and Placket Machines

- Cutting Equipment >

- Embroidery Machines

- Eton Systems

-

Feeders and Loaders

>

- Power Cradle

- Eastman Power Feeder - Sewn Products

- Power Feeder with HD 3-Roll Stand

- Vertical Carousel - Sewn Products

- Vertical Power Roll Feeders- Sewn Products

- A-Frame Roll Rack

- TFD Series

- Heavy Duty Roll Lifts

- Roll lift Jumbo- 70"

- Roll lift Low profile

- Roll lift standard

- Roll lift high rise

- Roll lift compact - 2

- Power Roll lift high rise

- Fusing and Heat Transfer Machines

- Label Pickers

- Measuring and Inspection Machines

- Needle Detection

- Paper

- Parts and Supplies >

- Phillocraft Spreading and Production Tables

- Plotters

- Pneumatic Lift Tables

- Production Tables - Phillocraft

- Quilting Machines

- Scissors, Snips and Shears >

- Sewing Machines

- Slitters

- Spreading Machines >

- Steam Press and Finishing

- Swatch Equipment

- Thread

- Thread Trimmers

- Ultrasonic Equipment >

- Upholstery Equipment

- Digitizer

- Used Equipment

- Webbing Cutter Machine >

- Tradeshows

- Service and Repair

- Manuals

- About Us

- Contact Us

- IDEAS

- Finance and Lease

- Sewn News

RSS Feed

RSS Feed