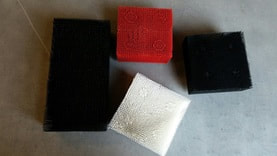

Bristle Blocks

Bristle blocks are often used on automated cutting machines because they provide several benefits that make them an ideal cutting surface:

- Versatility: Bristle blocks can be used to cut a wide range of materials, including fabrics, leather, foam, and other soft materials. This makes them a versatile tool that can be used in a variety of industries, such as textile and furniture manufacturing.

- Precision cutting: Bristle blocks are designed to hold materials in place during cutting, which helps to prevent shifting and ensure precise cuts. This is particularly important for materials that require precise cuts, such as fabrics and leather.

- Reduced material waste: Bristle blocks are designed to minimize material waste by holding materials in place during cutting. This helps to reduce material waste and save on material costs.

- Increased production speed: Bristle blocks can cut multiple layers of material at once, which can increase production speed and efficiency. This can help businesses save time and money by reducing labor costs and increasing output.

- Improved safety: Bristle blocks are designed with safety features such as safety guards and emergency stop buttons to prevent accidents and ensure operator safety. This can help businesses avoid accidents and injuries in the workplace.