Multi-Ply Cutting Machines

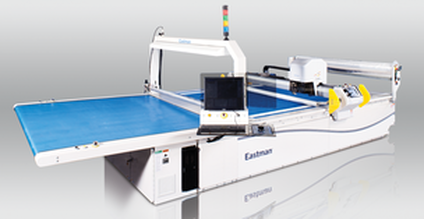

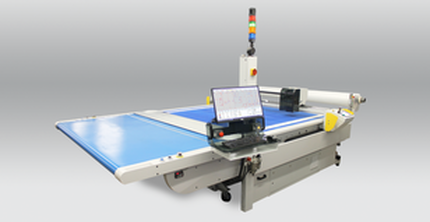

Eastman Raptor Series Cutting System

|

Features:

-Heavy-duty frame, gantry and tool head design -Modular tool head and frame components -Improved access for maintenance and replacement of internal components and consumable items -Sensors for monitoring optimum cycle speeds -Direct knife cooling improves cutting speeds and the ability to cut heavier-ounce materials -Cutting area is made up of durable bristle blocks -Reciprocating knife blade penetrates bristle blocks with precision and minimal damage to cutting area -Easy to replace, the bristle blocks snap-in and snap-out individually, featuring a unique design for maximum life -Blast gate reduces time in advancing material -Optional overhead light maximizes visual inspection of parts |

|

Specifications:

-Width: 78 inches (2.0 m) / Overall width 110 in. (2.79m) Custom widths available, contact the factory for additional information. -Length: 7.5 ft. (2.3m) Overall length 19 ft. (5.79m); 6.6′ (2.01m) unloading conveyor -Drive System:Dual-X Axis, Y-Axis & Theta Axis. X-Axis Rack & Pinion Drive, Y-Axis Belt Drive Brushless Servo motors -Electric Control Power: 208/230/380/460/575V, 3 ph, 50/60 Hz, 9.0 kVA -Electric Vacuum Blower: 208/230/380/460/575V, 50/60 Hz, 30 HP, VFD control |

-Pneumatic: 90 psi (6.2 bars), 18 cfm -Maximum Cutting Speed: Up to 40 in./sec (Up to 60m/min) – material dependent -Maximum Conveyor Speed: 8 in./sec. (12m/min) -Maximum Acceleration: 0.8 g -Compressed Air Consumption: 21 CFM -Reciprocating Knife Speed: Variable up to 5,000 RPM -Sound Level: <76 dB(A) -Operating Temperature: 55 – 100°F (12 – 37°C) -Humidity:20-80% (non-condensing) |

Safety:

-Six remote emergency stops: two on cutting gantry, four system-mounted

-Additional gantry-mounted stop disks pause system operation until returned to neutral and reset. Operation can then be resumed from any position.

-Tool head is equipped with plexiglass safety window to keep hands free of potential knife injury during operation

-Single turn-off point with a universal power system for lockout/tagout safeguards employees from unexpected start-up

-Stack light indicator marks operation status

-Six remote emergency stops: two on cutting gantry, four system-mounted

-Additional gantry-mounted stop disks pause system operation until returned to neutral and reset. Operation can then be resumed from any position.

-Tool head is equipped with plexiglass safety window to keep hands free of potential knife injury during operation

-Single turn-off point with a universal power system for lockout/tagout safeguards employees from unexpected start-up

-Stack light indicator marks operation status